The London Orthotic Consultancy prides itself on being at the cutting edge of orthotic design and manufacture.

Because our orthotists assess, scan, aid in the manufacturing process and fit the final product to the patient, we can ensure consistency and the highest orthotic quality. It also increases the chances of finding a successful resolution to the biomechanical problem quickly.

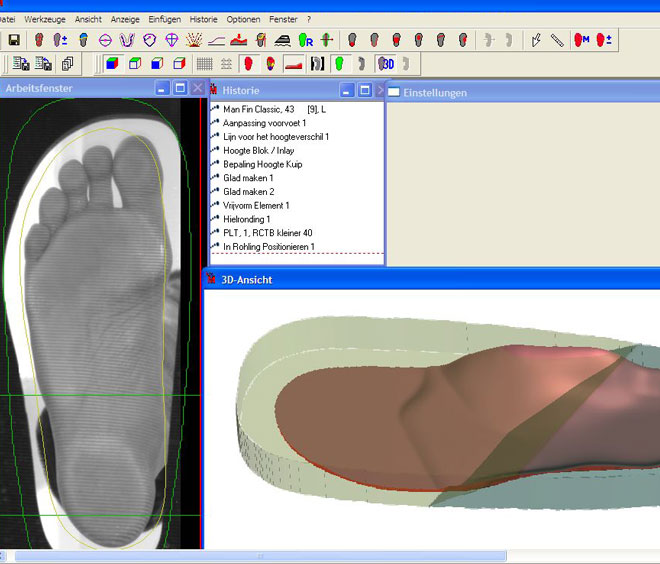

During the initial consultation, we use a Paromed CAD/CAM scanning system to produce a three-dimensional image of the sole of the foot. Every foot is unique, so capturing the exact shape of the foot is essential for providing an accurate clinical image.

We do this with the patient sat down, in a semi-weight bearing position and then correct the foot to what is the best clinically appropriate position.

We then determine the amount of wedging or modelling, that is required under the fore and hind foot using a clinical tool called micro wedge with three-dimensional computer-aided design (CAD). We use this to work out how much relief is required to return the foot to a corrected position, which is customised to each patient.

The London Orthotic Consultancy (LOC) is able to provide a complete range of footwear, from simple, extra volume high street-style shoes, to complex, bespoke orthopaedic and diabetic footwear. We understand that our clients want to have something that looks as stylish as possible while enabling them to walk in comfort.

We use a range of suppliers that offer a unique service in terms of quality and design. Our suppliers include some of the most experienced shoe manufacturers in the country, but we also source from new, innovative companies who are at the forefront of footwear design in Europe.

Patients have three options when deciding on the type of footwear that is suitable. The decision will primarily be based on your specific foot type or condition. The options are:

Your orthotist will guide you in terms of what is possible, given your foot shape and condition. Once the shoe type has been chosen and measurements taken, we can give you an exact quote for the costs involved.

Having determined what we think is the best form of wedging for the foot, the raw scan is then modelled using the same Paromed 3D modelling software where we insert wedging and add depth to different parts, such as the heel cup or the height of the arch. These all affect how the foot moves. We can also assess whether the patient would benefit from other modifications such as proprioceptive nodes which will be added at this stage.

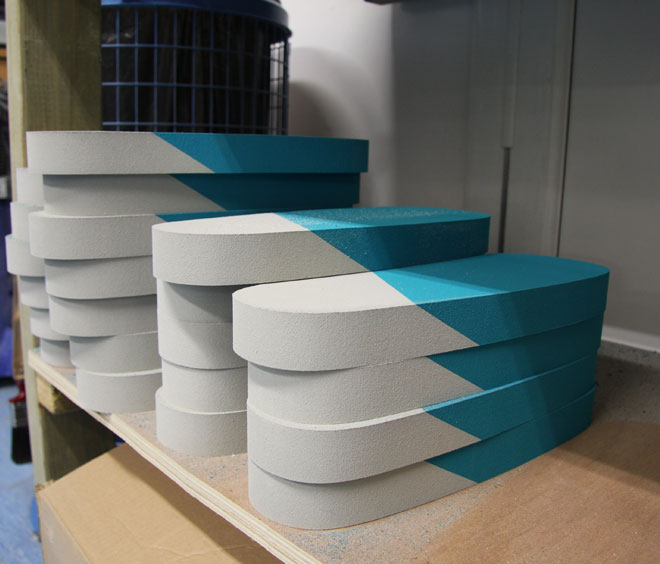

The final modified 3D files are sent to our six-way Paromed milling machine, which manipulates a robotic arm on the end of a drill bit to carve out the insole from a blank of ethylene-vinyl acetate (EVA).

The block of material will have varying degrees of density-dependent on the patient’s individual needs and which type of shoe they intend to be worn in.

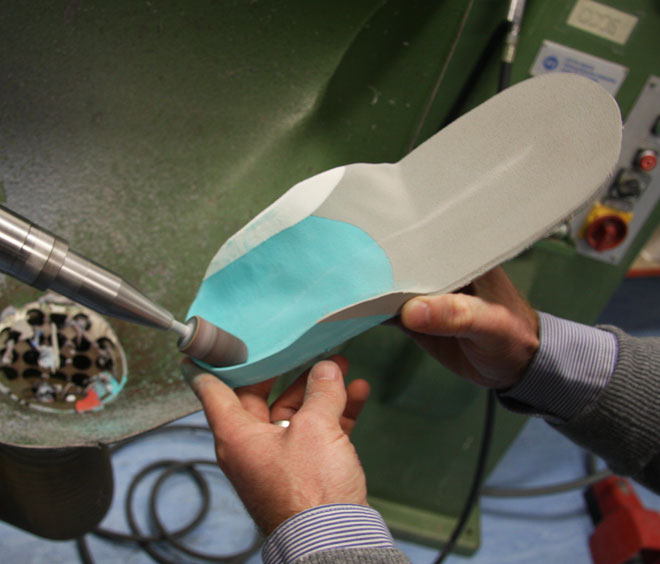

After the milling process, the insoles are cut from the blank and then filed down to the appropriate size and smoothed out by an orthotist.

Above: Raw material

Above: Raw material after Paromed milling

Above: Insoles being prepared

Our clinicians are highly qualified with a vast amount of experience in the manufacturing process of orthotics, and very often it will be the same clinician who sees the entire process through to completion.

If your orthotic insoles do not fit after the initial manufacturing process, or if they require adjustments, we can make modifications quickly and efficiently and aim to have them adjusted on the same day where possible.

An insole is a contoured orthotic device which alters the characteristics and biomechanics of the foot and ankle area. Biomechanics are concerned with mechanical laws and how they affect the living body, especially the musculoskeletal system.

They are removable devices, often made from plastic, that are designed to fit inside a shoe to provide additional support for your feet. As well as offering shock absorption, an insole can help distribute the weight of your body more effectively across the foot and can be made bespoke to cover a range of biomechanical conditions.

If you have symptoms in your feet, ankles, hips or your lower back that are intermittent or were not there to start with in early life, and have started to cause you pain over a period of time, bespoke orthotic insoles could be an excellent option.

If you have already tried rest, icing, compression and elevation and your feet have not recovered, we recommend a biomechanical assessment to consider the possibility of insoles. They are a non-invasive approach to treatment and in many cases, are a great option for symptoms that are not severe enough to warrant surgical intervention. Alternatively, they can be considered as an option prior to surgery.

We will send patients away when an insole is not appropriate, if a patient is suffering with iliotibial band syndrome for example, the problem can be helped with physiotherapy and a stretching programme. That’s what our biomechanical assessment is all about; determining whether there would be any benefit from altering the alignment of your feet.

Every physical and medical intervention carries a risk of ineffectiveness, even surgery as the most extreme form can fail. There is substantially more scientific evidence for the efficacy of bespoke foot orthotics than not, and our clinicians have successfully treated countless patients for a range of conditions over the years, all using our bespoke orthotic insoles.

It is important to acknowledge the difference between custom-made insoles and pre-fabricated, ‘off-the-shelf’ insoles which can be purchased cheaply. We offer an orthotic insole service that is thorough and takes a detailed look at your feet using advanced orthotic technology and software. We believe this gives us a leading advantage over other clinics. That combined with our highly qualified team means we can design orthotic insoles of the best quality and see them through to their manufacture, all onsite, which means the chances of finding a successful resolution to the problem are greater.

You can, and in some circumstances, a non-custom pair will resolve symptoms if the main problem is mainly to do with cushioning. Bespoke orthotic insoles provide an effective alternative once you have tried off-the-shelf orthotics and you can see some improvement in your symptoms, but not enough to feel like you can go about daily activities or return to sport for example. At this point, increasing the biomechanical support of the foot could be a way forward.

Most people visiting running shops are offered insoles as part of a deal when buying new trainers but often do not have anything necessarily wrong with their feet, they are asymptomatic. The insoles supplied by most running shops have standard contouring under the plantar surface – or the sole – and will be determined by looking at the foot on a treadmill. Normally you will be given one of three grades of insole that have a non-specific profile. They are designed to be more flat, so that they do not cause any problems when you start running in them.

At best, they can offer cushioning, but they are unlikely to treat any specific conditions or symptoms you may be suffering from, as ultimately runner shop insoles are not manufactured for you, they are a stock product with light customisation.

The Paromed technology and software we use at LOC uses a 3D scan to take a precise copy of the bottom of your foot to work out the exact distribution of pressure, no two insoles we produce will look or perform in the same way.

Insoles are made from varying densities of a plastic called ethylene-vinyl acetate (EVA) which is a plastic that can be reinforced if necessary. The density changes depending on the amount of cushioning and support required, and can be split throughout any insole. Higher density EVA will often be used towards the back of the foot, where more support is generally required, and lower density EVA to the forefoot where more cushioning is needed.

We can also produce insoles from carbon fibre which are suited to more supportive orthoses, however carbon fibre cannot be manipulated once it has been milled out. While it provides excellent support, it is not always the most appropriate of materials.

No one fully knows what causes bunions to form, certainly family history plays a part, as do ill-fitting shoes and shoes which are too narrow but also a mechanical history of overpronation when the foot rolls inwards as you walk, can be a factor.

The technical term for bunions is hallux valgus, and although more studies are required, anecdotally we have seen that bunions can be aided by an insole holding the medial arch up for longer while walking, which can slow the rate at which a bunion develops or worsens. Although we cannot help with the hereditary aspect, we can advise on footwear and determine if the mechanics of the foot can be improved through biomechanical assessment.

It largely varies dependent on the patient’s individual requirements, but often our insoles can be made on the same day or as quickly as the next.

We do offer our express insole service which takes 2 hours from initial assessment to manufacture and fitting. We open late on Monday, Tuesday and Thursday evenings late until 19:00 to accommodate for people who would like the express service after working hours.

Many common foot conditions can lead to irregular posture, back pain and gait (walking pattern) including plantar fasciitis, bunions, overpronation (when the foot rolls inwards as you walk) or supination (foot rolls outwards). Compromised posture in the back, particularly in the lower back, can often be a result of poor alignment in the feet.

In theory, any biomechanical malfunction in the foot or ankle can result in poor posture and back pain, as well as the knees and hips. If a bespoke insole can realign the joints and allow the soft tissue in the back to heal, this can reduce pain. Once we have carried out a biomechanical assessment, we can establish whether you would benefit from bespoke insoles.

Proprioceptive insoles have specific adaptations, like nodes, added to the top surface of the insole in order to stimulate nerve clusters on the plantar surface of the foot in a different way so that when you walk, the nerves in the foot are stimulated to provide more feedback as it is bearing weight.

Proprioceptive nodes are not required for runner’s insoles but are helpful to patients with a neurological deficit. They help with sensory feedback to improve balance and give the brain more information about your positioning every time your foot hits the ground, which should help you walk more naturally.

Join The London Orthotic Consultancy in celebrating Cerebral Palsy Awareness Day on March 25th. Learn just how important expert orthotic care is in enhancing mobility, independence, and quality of life for children and adults with cerebral palsy.

Introducing the Agilik™ smart orthosis, a cutting-edge, powered knee orthotic now available in the UK through the London Orthotic Consultancy. Unlike traditional KAFOs or heavy exoskeletons, the Agilik™ provides dynamic knee assistance and offers real-time support, reducing fatigue and improving posture. This pioneering, modern technology can help children and adults with lower limb weakness walk more efficiently and naturally. We are honoured to be selected as the exclusive paediatric specialist centre in the UK for the Agilik™ device.

When Sophie noticed her baby Max had a persistent flat spot on his head, she was told it would resolve naturally—but it didn’t. Seeking a second opinion led her to the London Orthotic Consultancy, where Max was diagnosed with severe plagiocephaly.

A little more than four years after the LOCband Lite's launch, we're proud to have successfully treated our 250th helmet therapy patient at our Romford clinic using our cutting-edge 3D-printed cranial band. After five months of treatment, her final scan showed that her asymmetry had decreased from 12 mm to 3 mm.

Sky News published an article this month quoting scientists at Southmead Hospital who claimed there was a lack of research into flat head syndrome and its treatment with cranial remoulding (helmet) therapy. This is our response.

With our non-surgical treatment plan, Alex achieved 100% chest correction in just two years. His treatment involved a combination of dynamic chest compressor and vacuum bell therapy treatment to address his pectus excavatum and rib flaring.

Learn how a custom carbon fibre AFO helped Gill regain mobility and comfort despite complex challenges from shin bone (tibia) removal. We created a truly tailored orthotic solution made from pre-preg carbon fibre at our Cambridge clinic.

Discover how bespoke orthotics and the OSKAR program with Elaine Owen transformed Archie’s life with cerebral palsy quadriplegia, helping him avoid a wheelchair and achieve greater mobility.